ISO 9001:2015

Overview

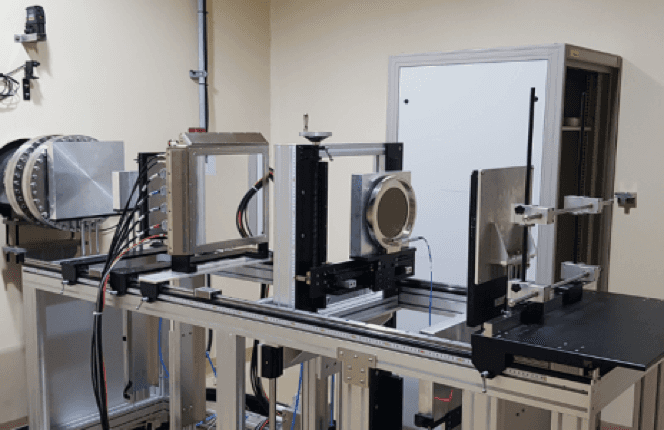

Scutum R is an advanced radiation shielding solution designed specifically to broaden the usability of commercial off-the-shelf (COTS) components in space missions. We provide in-depth analysis and predictive modeling of the harsh space environment—including radiation exposure, extreme temperatures, and structural shocks—tailored to the expected mission profile and lifetime of your satellite. Leveraging Space&Bean’s innovative shielding material technology, we design and manufacture custom radiation-shielded housings optimized for COTS components. This not only guarantees the reliable performance of your electronics in orbit but also offers a cost-effective pathway for building high-performance satellites.

Detail

Our core service, FRIDAY (FAST RADIATION IMPACT DETECTION AND YIELD), delivers comprehensive radiation impact assessment and advanced consulting for COTS component optimization, ensuring that even non-standard parts are fully qualified and ready for real-world space missions. Additionally, Space&Bean develops a range of satellite subsystems—including proprietary attitude determination and control systems (ADCS)—enabling us to provide integrated solutions to meet diverse mission requirements. With Scutum R, experience new standards in reliability, innovation, and cost competitiveness, and unlock the full potential of COTS components for your next space venture.